14 months ago, I wrote The case for synthetic fuels manifesto to detail exactly how Rivan plans to produce the cheapest synthetic fuels on earth. We’ve recently raised £10m (media coverage here) led by Plural to bring that plan to life. This is year ~ 1 of our 20 year plan.

What does Rivan do?

Rivan designs, manufactures and deploys synthetic fuel plants. Our mission is to make life sustainable on earth, by making it cheaper to pull fuels from the air than drilling them from the ground. We see this as a purely thermodynamic, and thus an energy cost (Opex) and infrastructure cost (Capex) challenge.

Our approach is simple:

- Rivan uses simple, robust hardware designs, and vertically integrates all engineering and manufactures in-house (minimising infrastructure Capex).

- Rivan designs and deploys its own solar to produce the cheapest DC electricity in the world (Enabling cost-competitive production output).

This strategy is designed to capture gigatonnes of the excess CO2 from air by creating a valuable gross-end product from the captured carbon (synthetic fuels), that will help to decarbonise heavy industry and build energy security in the UK and Europe.

Rivans’ first product is a modular 1MW modular synthetic fuel plant, comprised of DC off-grid solar, an alkaline electrolyser to produce hydrogen from water, a direct-air-capture system to capture CO2 from 400ppm air, and a Sabatier reactor to combine these products both to produce 99.9% pure CH4.

This CH4 is injected directly into the existing gas network (no modifications needed) and distributed throughout the continent, providing a cheap, chemically identical but decarbonised drop-in replacement for fossil fuels.

What have we achieved so far?

Rivan is almost entirely focused on increasing iteration speed of our engineering. Over the last 12 months, we’ve built a team of 20+ talented engineers and deployment specialists to help accelerate that timeline. Some key milestones along the way:

- 100kW pilot site live

Rivan has commissioned a 100kW pilot plant in the UK. The pilot demonstrates end-end production from solar energy in, to CH4 out. The plant is designed to validate our vertically integrated design on a large-scale, and act as a test-bed to rapidly iterate and scale our designs over the next 6-9 months:

- 100kW reactor

Custom designed Sabatier reactor that achieves 99.9% conversion with large operating envelope to follow solar irradiance:

- 100kW reactor injection system

We’ve designed an ultra-low cost reactor injection system that mixes, analyses, compresses and feeds our reactor the perfect mix of H2 and CO2 to achieve total conversion. This will, overtime, be integrated more directly into our reactor sub-system rather than its current independent state.

- DAC system R&D

We’ve built a calcium oxide looping DAC system from scratch, including oxide hydration, hydroxide forming, carbonation and humidification bed, and calcination kiln. Our focus is to now scale and integrate this system. Here’s Sam Doyle (Mechatronics Engineer) and Gruffydd Gozali (Mechanical Engineer) working on our hydroxide forming stage:

- 100kW electrolyser

We’ve now deployed a simple, robust Alkaline water electrolyser, designed and manufactured in-house. Our goal is to achieve <£2/kg hydrogen over the next 1-2 years, to feed our reactor and reduce LCOM (levelised cost of methane).

- Low-cost, autonomous control system

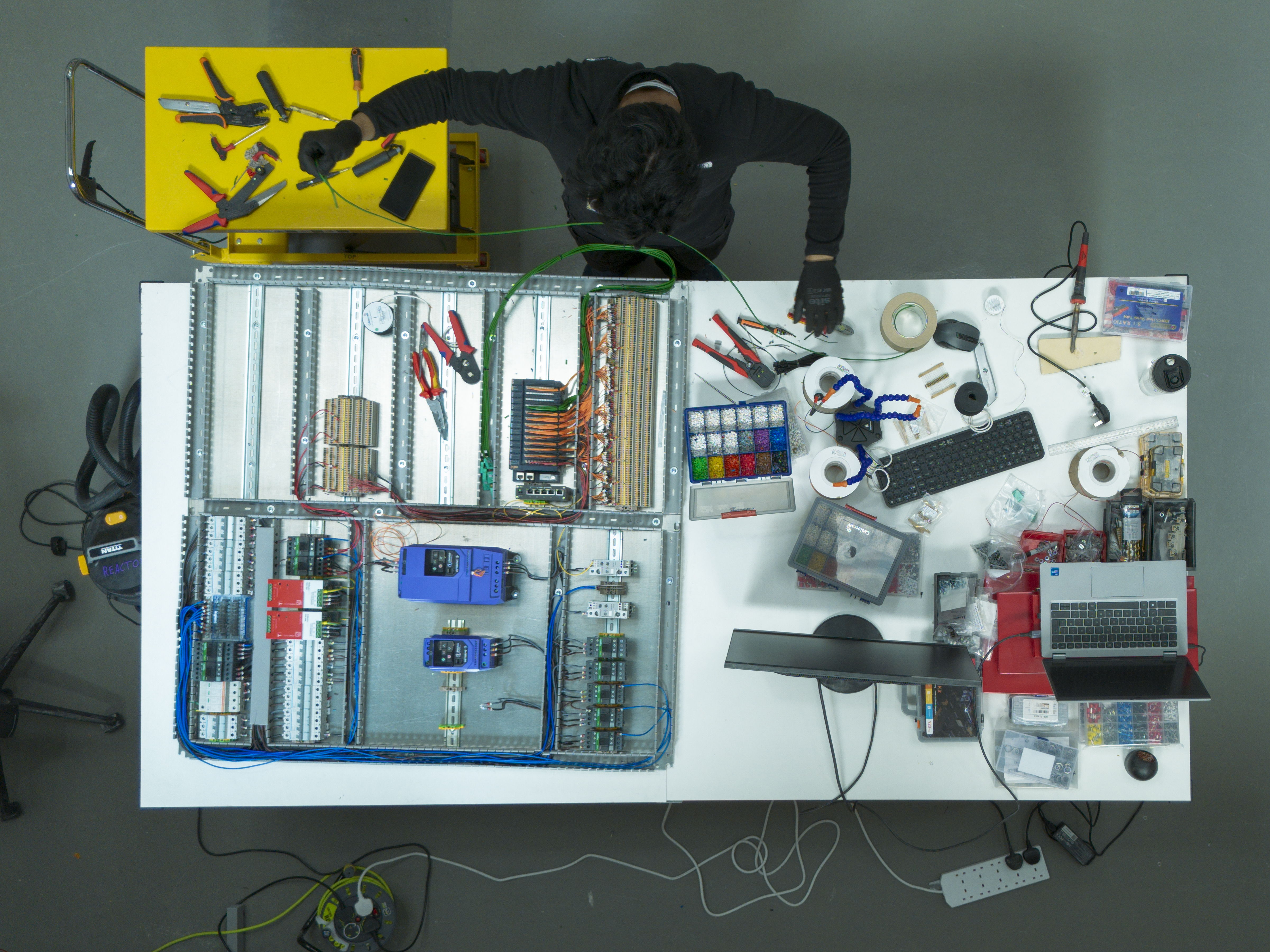

As our plants are required to operate off-grid and autonomously, our control systems have to be sophisticated and built from scratch. We’ve developed a low-cost, robust control system (both hardware and software) to control our plants safely and remotely. This system is now being tested at our pilot site. Here’s Abhijeet (Electrical Engineer) working on one of our electrical cabinets:

What are we focused on now?

- Integrating our sub-systems

For speed and safety, we made the decision to isolate each sub-system for our initial pilot deployment. This allows us to iterate quicker with fewer dependencies. We’re now working to integrate these systems to form a more compact, homogenous plant.

- Scaling our entire system up

Our 100kW system provides a great base to now scale our systems to 1MW+. To do this effectively at cost, we’re utilising the operational data from our pilot site to influence architectural decisions focused on robustness and LCOM.

- Manufacturing and cost reduction

We are now aggressively planning manufacturing and process cost reductions. Initially we wanted to validate our technology, before scaling production to 100’s and 1000’s of units. Our aim now is get rapidly to a state where we have a 1MW modular unit design that we can manufacture at scale, at low cost.

Why is this important now?

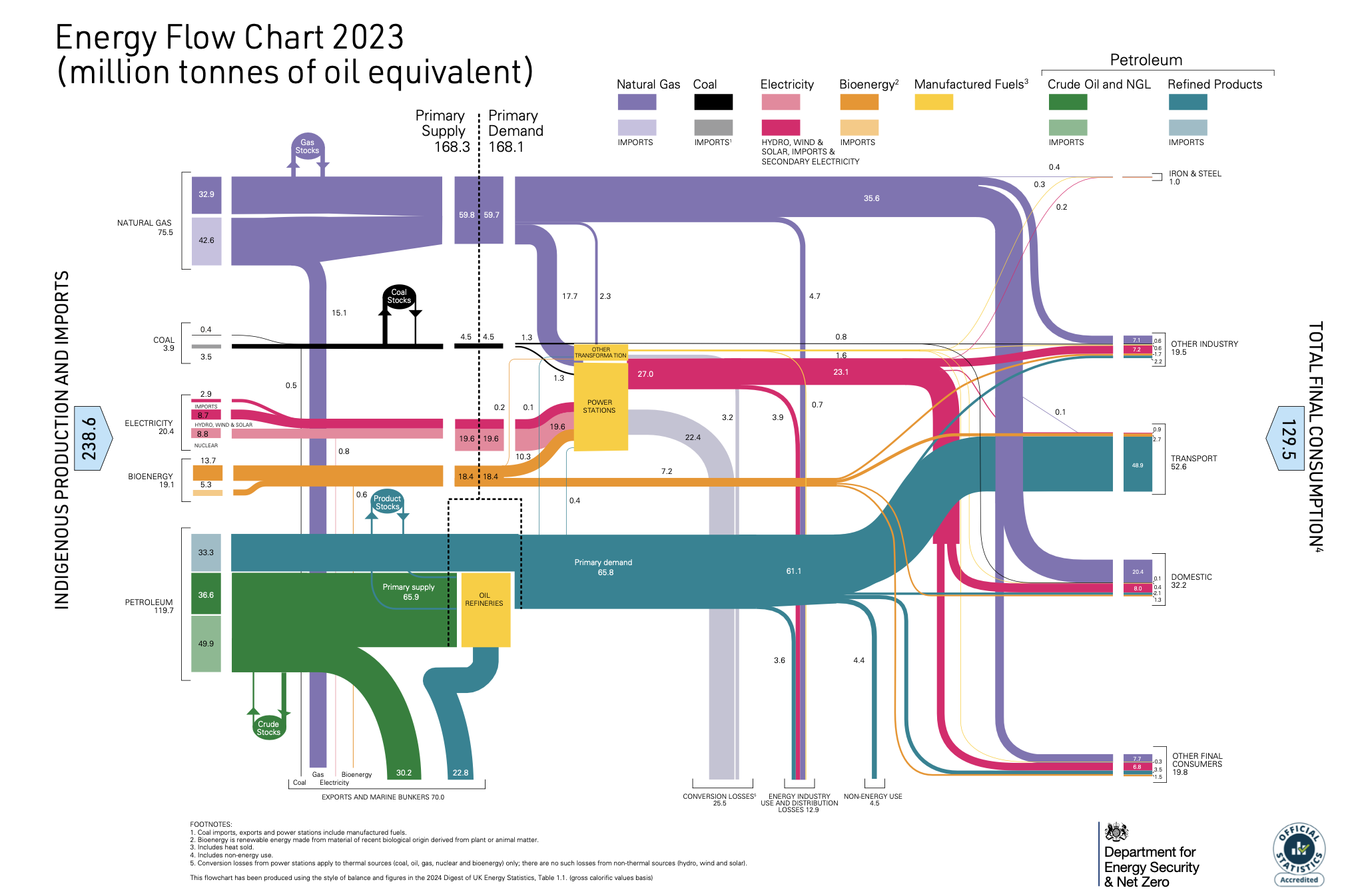

The UK’s energy security depends almost entirely on reliable, and scaled domestic production. As of today, roughly 40% of our primary energy (oil, gas) is imported from fossil sources. This large dependency on imports, combined with a lack of storage (the UK has around 7 days of peak gas storage, in contrast to Spain, France and Germany that all have >100 days of storage), means the UK is exposed to market fluctuations that cause aggressive price spikes. Since energy markets follow simple demand & supply dynamics, and energy demand is very inelastic (e.g it takes an extreme price increase for demand to dip, as fundamentally consumers still need to get to work, cook, heat, produce etc), when supply is short and we need energy, we pay the price. The black swan events of the Ukraine war and COVID showed how leveraged the UK has become by global energy market.

Although the Governments Energy security strategy supports efforts to increase domestic production, most areas suffer from either a lack of market maturation or prohibitively high costs. For example, there are only 4 green-hydrogen plants with a daily production >100kg live in the UK, suffering from a lack of structured market, extremely poor distribution, storage, lack of end-utility, and prohibitively high costs of production. The same can be said for Nuclear, where LCOE will likely be 3-4x that of solar, and 2-3x that of solar and batteries.

If the UK is to create a scaled domestic energy supply, the solutions must be inexpensive, robust, and easily distributed (including both distance travelled from production to consumption, and backward-compatibility with current infrastructure). Large scale deployment of off-grid synthetic fuel plants can help achieve that future.

If you want to work on critical infrastructure with a world-class engineering team, please apply to any of our open roles here.